Fine Blanking Parts Manufacturers in Chennai – SJ Technologies is a best Fine Blanking Parts production division, the products are good stability and reliability, high degree of automation, high production efficiency, simple operation and ergonomic. For localization of high-end intelligent fine blanking equipment, raise the capacity of fine blanking production, After years of research and development, design and manufacturing, 320 tons, 630 tons, 700 tons of hydraulic fine blanking machines have been successful production and operation.

Significant features of Fine Blanking

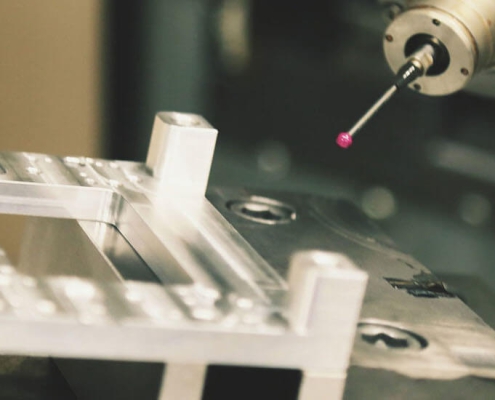

Fine blanking as a process is technology intensive and requires tooling that is precise and accurate. At SJ Technologies, we have the required infrastructure that enables us to produce parts of thickness between 1.6mm and 16mm with close tolerance.

Types of Fine Blanking Finished parts, better solution

Fine Blanking Line

Based on SJ Technologies’s excellent processing and manufacturing capacity and rich series of products, we have a complete set of fine blanking equipment for the fine blanking production line.

Fine Blanking Machine

SJ Technologies series CNC hydraulic fine blanking machine developed by SJ TECHNOLOGIES is high-end automation equipment with advanced technology, simple use, and precision and independent intellectual property rights.

Blanking Machine Refabrication and Maintenance

Cutting Edge of Fine Blanking Technology

SJ Technologies not only provides a full set of fine blanking production line equipment but also our technical team to provide comprehensive technical support and training services.

Fine blanking produces close tolerance parts from materials of higher thickness. Cut edge is 100% free of tear and in most cases parts are suitable for mechanical function without the need for subsequent machining. This technology enables productions of “Near net shape” and even ready to assemble sheet metal parts.

Working Principle of Fine Blanking

Compared to normal blanking, fine blanking operation is more precious, product high precision requirements, no collapse Angle, no burr, the full bright belt is the difficulty of stamping process, the use of ordinary blanking process cannot avoid burr, collapse angle.

Fine blanking technology is a special method to solve this kind of product.

Fine Blanking VS Stamping

Fine blanking originated from general stamping, but it is not simply an enhanced version of general stamping. The essential difference between the fine blanking process and the general blanking process is that the general blanking cannot effectively avoid the generation of tears in the section when punching, while the fine blanking tries to inhibit the occurrence of tears in the sheet material by all means when punching.

The following are the differences between fine blanking and general stamping.

Difference in requirements of materials to be processed

Ordinary stamping can process almost any material, as long as the die steel is strong enough and the press pressure is sufficient.

However, the materials used for fine blanking require good plasticity, low flexural strength ratio and high elongation of the material to be processed because of the need to effectively transfer compressive stress between material crystals to inhibit cracking.

Differences in processing capacity characteristics

General punching limit size

Stamping: Minimum hole diameter of 1.5 times the material thickness.

Fine blanking: minimum whole diameter up to 0.6 times the material thickness.

Our Services :

CNC Wire Cutting Job Works in Chennai, CNC Wire Cutting Job Works in Ambattur, EDM Wire Cut Job Works in Chennai, EDM Drill Job Works in Ambattur, Fine Blanking Parts, Press Tool, Moulds .

Testimonials

FAQ’s

What is fine blanking parts?

Fine blanking (also known as fine-edge blanking) is a special type of stamping process that produces parts of enhanced accuracy, flatness, and edge characteristics when compared with conventional stamping.

What is the fine blanking method?

Fine Blanking is a unique development in the metal forming industry that applies precision mass production techniques. Although innovated from traditional metal stamping, Fine Blanking employs a system of machine movement, tooling and plastic deformation of metal.

What are the components of a blanking tool?

Blanking tool consists of two main parts, a punch and a matrix. The matrix fulfill the bottom function of the hard knife and the punch fulfill the upper function of the knife, the cutting press tool. At the same time, there are guiding elements: guide plate, guide posts and column guide sleeves.

What is the difference between blanking and fine blanking?

Definition. Both blanking (stamping) and fineblanking are processes for producing sheet metal parts. Fineblanking is a highly sophisticated technology for the production of high-precision three-dimensional stamped parts.

Which press is used for fine blanking?

Hydraulic fineblanking presses are noted for extreme precision of the slide guiding over the entire length and width directly on the press uprights.

Why is blanking used?

Furthermore, because the primary metal stock can be reused, blanking can help manufacturing firms reduce their material waste. Due to these benefits, blanking is commonly used to mass produce components for industries such as aerospace and automobile manufacturing.

Link to: Contact Us

Call Us

Reach out to us for more information and to discuss your visit.

Contact Us