Press Tool Manufacturers in Chennai – SJ Technologies is a renown manufacture, supplier and exporter of an exquisite range of socketing solutions to PVC Pipe Industry and other special purpose machines and press tools for distillery and packaging industries, we export our machinery in Chennai. Our main product line includes Socketing Machine. We are committed to delivering high-quality products within the proposed time frames committed to customer. Taking into account the different needs of a few enterprises, we are occupied with structuring and assembling tools, press tools, jigs and fixtures according to custom detail. We produce an extensive variety of Machine Tools and Dies that are accessible in an assortment of shapes and sizes. Also, we provide customized manufacturing and supplies of our range as per the requirements of our clients.

Elevate Your Manufacturing with SJ Technologies Press Tools

Special purpose machines and press tools are all admired for their perfect engineering. We also take care to warehouse and package the range accordingly, so that no mishap occurs while transit. Our diligent efforts make all our products cost-effective, while making them highly efficient at the same time. Due to this, we have gained a reputable status in Chennai.

We have outdone our competitors by adhering to supreme levels of quality, large-production capacity and providing customized solution services. Also, our timely project implementation, cost-effective productions and large product-line have helped us gain good customer satisfaction. It is due to his guidance and efforts that we have been able to bring our company to such a strong position in both domestic as well as international markets.

Process Of The Press Tool Manufacturing

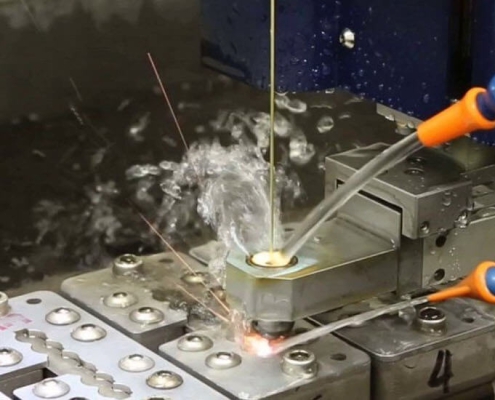

The manufacturing process for press tools, also known as stamping or die tools, involves a series of steps to create specialized tools used for metal stamping and forming operations. Here’s an overview of the press tool manufacturing process:

Design and Engineering:

Conceptualize the press tool design based on the specific requirements of the part or product to be manufactured.

Detailed engineering includes creating CAD (Computer-Aided Design) drawings and 3D models of the tool.

Material Selection:

Choose appropriate tool steel or other materials for the die and punches based on factors like hardness, wear resistance, and the type of materials to be processed.

Machining and Milling:

Use CNC (Computer Numerical Control) machines to shape and cut the tool components from raw materials. Precision machining is crucial to create the complex shapes and clearances required for the stamping process.

Heat Treatment:

Heats treat the tool components to achieve the desired hardness and toughness, ensuring they can withstand the forces involved in stamping.

Assembly:

Assemble the die and punch components, often with the use of alignment pins and fasteners. Ensure precise alignment to avoid any lateral or angular movement during stamping.

Surface Grinding and Polishing:

Grind and polish the tool surfaces to achieve a smooth finish. This step is essential for achieving high-quality stamped parts with minimal defects.

Testing and Quality Control:

Conduct thorough quality checks, including dimensional inspections and functional testing, to ensure that the press tool meets specifications and requirements.

Tool Maintenance:

Establish a maintenance schedule to inspect, clean, and maintain the press tool to extend its lifespan and optimize performance.

Installation and Setup:

Install the press tool into the stamping press or machine. Ensure proper alignment and clearance settings for the specific stamping process.

Stamping Operations:

The press tool is used in conjunction with a stamping press or machine to create parts or products from sheet metal or other materials. The tool is placed in the press, and the material is fed into the machine. The press applies force to the tool, which shapes and cuts the material into the desired form.

Regular Maintenance and Replacement of Press Tool

Over time, press tools experience wear and may require sharpening, repairs, or even replacement. Regular maintenance and monitoring are essential to ensure consistent quality in stamped products.

The manufacturing of press tools is a precise and detailed process, as the quality of the tool directly affects the quality and consistency of the stamped parts. Careful design, selection of materials, and maintenance are critical aspects of the process.

Our Services :

CNC Wire Cutting Job Works in Chennai, CNC Wire Cutting Job Works in Ambattur, EDM Wire Cut Job Works in Chennai, EDM Drill Job Works in Ambattur, Fine Blanking Parts, Press Tool, Moulds .

Testimonials

FAQ’s

How many types of press tools are there?

Generally press tools are categorized by the types of operation performed using the tool, such as blanking, piercing, bending, forming, forging, trimming etc. The press tool will also be specified as a blanking tool, piercing tool, bending tool etc.

What material is press tool?

SJ Technologies is widely used in cold forming molds, press tools, and die making industries, primarily due to excellent wear resistance, high compressive strength, greater dimensional stability, and high hardness.

How are press tools made?

With regard to the manufacturing processes of press tools, it is necessary to utilize three main manufacturing methods: stamping/coining (sheet metal pressing), machining (metal shaping by using rotating cutting tools like mills or lathes), and wire-cut EDM (Electrical Discharge Machining).

What is press tool and its types?

Press tools are commonly used in hydraulic, pneumatic, and mechanical presses to produce components at high volumes.

How are press tools classified?

Generally press tools are categorized by the types of operation performed using the tool, such as blanking, piercing, bending, forming, forging, trimming etc. The press tool will also be specified as a blanking tool, piercing tool, bending tool etc.

Which metal is used in press?

The Press machine is usually not exposed to a very high temperature. In this field, therefore, cold-work tool steels are primarily used in a press machine, supplemented by high-speed tool steels and sometimes hot-work tool steels.

Link to: Contact Us

Call Us

Reach out to us for more information and to discuss your visit.

Contact Us